You want your reach cylinder to last a long time, right? Start by doing regular hydraulic cylinder maintenance. If you check and clean your hydraulic cylinder often, you can stop expensive problems and save money. Easy steps like using the correct fluid and making sure parts line up can help your equipment last longer. Regular maintenance stops early damage and keeps everything working well. If you take care of your machines, you get more value and less stress.

It is annoying when your hydraulic equipment stops working. When machines are not running, you lose money. If your high pressure reach cylinder breaks, you might have to pay a lot. Some companies lose between $10,000 and $500,000 every hour their machines are down. Others say they lose $9,000 each minute when their hydraulic equipment fails. These costs can get very high, especially if you use many machines.

A worn-out hydraulic cylinder can leak and make more friction. This makes your pumps work harder and use more energy. Your energy bills can go up by 15%. Imagine if 20 excavators waste thousands of liters of fuel each year because of bad cylinders. Emergency repairs cost more than regular maintenance. If you take care of your machines, you can stop surprise breakdowns and save money over time.

Tip: Doing regular maintenance helps your hydraulic equipment last longer and keeps you from losing money when machines stop working.

Taking care of your hydraulic equipment does more than save money. It also keeps you and your team safe. If a hydraulic cylinder fails, equipment can fall or fluid can spray out fast. These problems can hurt people or even start fires. Here are some common dangers:

|

Risk Type |

Description |

|---|---|

|

Sudden Equipment Collapse |

Loads can fall without warning and hurt people. |

|

High-Pressure Fluid Ejection |

Leaks can shoot fluid into the skin and need quick medical help. |

|

Fire Hazard |

Hydraulic fluid can burn and cause fires at work. |

|

Loss of Control |

Machines can move in strange ways and hurt people nearby. |

|

Slips and Falls |

Leaked fluid makes floors slippery and people can fall. |

|

Psychological Stress |

Many breakdowns can make workers nervous and less sure of themselves. |

When you take care of your hydraulic system, your machines last longer. Good hydraulic equipment works well and is safer. You get better results, fewer accidents, and your team feels more confident. If you want your hydraulic equipment to last for twenty years or more, you need to care for it often. With good habits, your machines can work for millions of cycles and keep helping you.

You might not see dirt inside your hydraulic system, but it causes big problems. Tiny bits of dust or metal can get into the oil and scratch the inside of your hydraulic reach cylinder for excavator. Industry experts say dirty oil causes up to 80% of hydraulic component failures. When dirt gets in, it damages seals and smooth finishes. This leads to leaks and poor performance. If you want to prevent hydraulic cylinder failure, you need to keep your oil clean and change filters often.

Tip: Always check your hydraulic fluid for signs of dirt or cloudiness. Clean oil keeps your equipment running longer.

Lubrication helps parts move smoothly. If you use the wrong oil or forget to add enough, the rod can get damaged. Overheating happens when parts rub together without enough oil. This can make the rod bend or break. Damaged rods hurt seals and other parts, which can stop your hydraulic cylinders from working right.

Seals keep oil inside and dirt outside. Over time, seals wear out or get damaged. You might see oil leaking under your machine or notice a drop in fluid levels. Sometimes, you hear strange noises or feel more vibration. Slow movement or less power means your cylinder might have a leak. Worn-out rod seals, cracked barrels, or damaged O-rings all cause leaks.

|

Sign of Seal Problem |

What You Might Notice |

|---|---|

|

Leaking Fluid |

Oil spots or puddles |

|

Reduced Performance |

Less lifting power |

|

Slow Cylinder Movement |

Delayed response |

|

Overheating |

Hot surfaces |

|

Noise and Vibrations |

Knocking or shaking |

If your cylinder is not lined up right, it puts extra stress on the parts. Too much weight or force can bend the piston rod or even crack the barrel. Misalignment wears out seals faster and causes leaks. When you push your equipment past its limits, you risk breaking it. Always use your machines the way the maker suggests to avoid early failure.

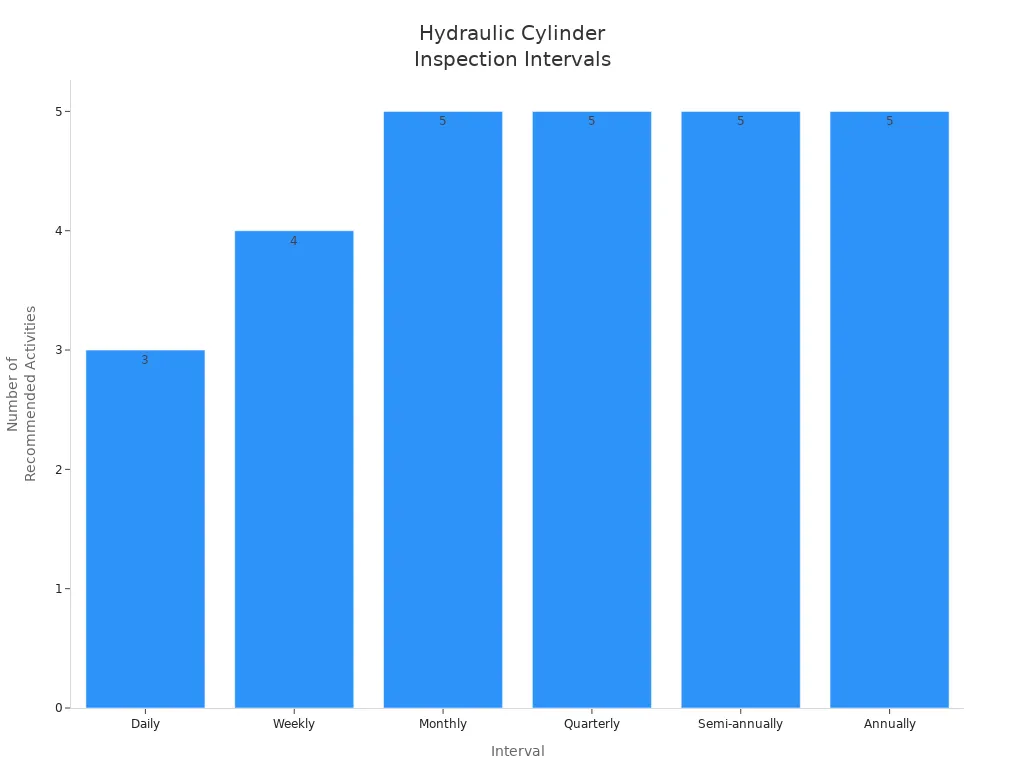

You want your reach cylinder for reach truck to last a long time. Start by checking and cleaning it often. Look for leaks or damage every day. Wipe the cylinder and the area around it. If you do this daily, you can find problems early. Here is a simple schedule you can use:

|

Interval |

Activities |

|---|---|

|

Daily |

Look for leaks or damage. Listen for strange noises. Check fluid levels. Clean the cylinder and area. |

|

Weekly |

Check the rod for wear or rust. Make sure it has enough oil. See if everything lines up. Watch the system pressure. |

|

Monthly |

Clean everything well. Check seals. Look at hoses and fittings. Test how it works with weight. Check fluid quality. |

|

Quarterly |

Inspect everything closely. Test the oil. Change filters. Clean the reservoir. Check gauge settings. |

|

Semi-annually |

Look at all parts in detail. Check for inside damage. Test without breaking anything. Change old parts. Reset safety devices. |

|

Annually |

Take everything apart and check it. Change seals and bearings. Replace worn parts. Flush the system. Write down what you did. |

If you follow this schedule, you can catch small problems early. This helps you avoid big repairs later. Regular care keeps your equipment safe and working well.

Picking the right hydraulic fluid is very important. If the fluid is too thick, the cylinder wears out faster. If it is too thin, dirt can get in and parts are not protected. Here is what happens if you use the wrong fluid:

|

Viscosity Type |

Consequences |

|---|---|

|

High Viscosity |

More wear because of poor lubrication. More friction means more power needed. The machine works less well. |

|

Low Viscosity |

Dirt gets in and parts wear out faster. The machine works less well and parts are not protected. |

Always read your machine’s manual to find the right fluid. This easy step saves money and helps your cylinder work better.

Lubrication helps your cylinder move easily. Use the right oil made for hydraulic systems. Here are some tips to help you:

Pick the correct oil for your machine.

Oil your cylinder on a regular schedule.

Check the oil often. Look for dirt, water, or if it feels different.

If you keep up with oiling, you lower friction and wear. Your cylinder will last longer and work better.

You need to keep dirt and water out of your hydraulic system. These things can cause big problems. Here are ways to keep your system clean:

Use good filters with the right size.

Store fluids carefully. Keep containers closed and clean.

Use a filter pump when adding new fluid.

Clean connectors before hooking them up.

Use clean, high-quality fluids made for your machine.

Check and clean parts often with a good maintenance plan.

If you do these things, you stop most problems before they start. Clean fluid means fewer breakdowns and longer life for your equipment.

Alignment is very important for your hydraulic cylinder. If things are not lined up, parts wear out faster. Check alignment every month. Check again after moving your machine. If you hear strange sounds or see slow movement, check alignment right away.

Here is a quick checklist to help you:

Look at mounting points for damage.

Make sure the rod moves straight and does not rub.

Check for bending or twisting.

Fix anything that is not lined up.

If you check and fix alignment often, you avoid many problems. Good inspections help you find trouble early. This keeps your cylinder working well and helps it last longer.

Tip: Always check alignment. It is one of the best ways to stop early failure and keep your equipment working smoothly.

You want your reach cylinder to work well every day. Seals and O-rings play a big role in keeping everything running smoothly. If you check them often, you can spot problems before they get worse. Here’s what you should look for:

Cracks or cuts on the seal surface

Hard or brittle texture

Swelling or soft spots

Oil leaks around the seal area

Dirt or grit stuck to the seal

When you do regular seal inspection and replacement, you help stop leaks and keep your hydraulic system strong. Seals and gaskets act like guards. They keep oil inside and block dirt from getting in. If you see any damage, you should fix it right away. You also need to make sure the seals have enough lubrication. Dry seals wear out faster and can cause leaks.

Tip: Always check the temperature and pressure in your system. High heat or pressure can make seals wear out faster.

A quick look at your seals can save you a lot of trouble. If you keep up with these checks, your equipment will last longer and work better.

You might wonder when it’s time to change a seal. Here are some signs that tell you it’s time for a new one:

You see oil leaking from the cylinder

The cylinder moves slowly or feels weak

Seals look worn, cracked, or broken

You hear strange noises or feel extra vibration

If you notice any of these, don’t wait. Replacing broken seals is a smart way to prevent bigger problems. Sometimes, you may need to replace the whole part if the damage is bad. It’s also important to find out why the seal failed. Fixing the cause helps you avoid the same issue again.

|

Sign of Seal Failure |

What You Should Do |

|---|---|

|

Visible leaks |

Replace the seal |

|

Faulty operation |

Inspect and replace |

|

Worn or cracked seals |

Replace right away |

|

Recurring problems |

Check for deeper issues |

Regular maintenance and quick action keep your reach cylinder in top shape. You get fewer breakdowns and more time working.

You want your equipment to last a long time. Scheduled maintenance is a great way to help your cylinder last longer. If you follow a regular plan, you can find small problems early. This stops them from turning into big problems. Here are some things that happen with scheduled maintenance:

You notice wear and tear before it gets bad.

You find dirty oil or other things that should not be there.

You stop breakdowns and keep your machines working.

You make your hydraulic cylinder work better and last longer.

Look at how much money you can save over time:

|

Benefit |

Description |

|---|---|

|

Reduced Downtime |

Regular checks stop failures, so your machines work more and spend less time waiting for repairs. |

|

Extended Equipment Life |

Routine care lowers stress on parts and helps you wait longer before buying new ones. |

|

Improved Energy Efficiency |

Well-cared-for systems use less energy, so you save money. |

|

Lower Repair and Replacement Costs |

Fixing things early stops small problems from becoming big, expensive ones. |

|

Enhanced Reliability and Safety |

Regular service keeps your equipment safe and helps protect your team. |

You need to watch how your hydraulic cylinders work every day. If you check pressure and load, you can find problems before they get worse. Here are some things you should look at:

Filter condition: If pressure goes up, you might need a new filter.

Leaks: Look for oil loss or drops in pressure.

Temperature: High heat can hurt oil, seals, and parts.

Vibrations: Shaking or weird movements can mean loose parts.

Pressure behavior: Changes in pressure can show problems with pumps, valves, or the cylinder.

Speed and position: Make sure the piston moves at the right speed and stops in the right place.

Load control: Check that the cylinder handles the right amount of force.

If you check these things often, your equipment will stay safe and work well.

You can stop most big problems if you find them early. Start with easy steps:

Look for leaks and listen for strange noises.

Test how the cylinder moves. If it moves in a jerky or slow way, there may be a problem inside.

Watch for rod movement that looks wrong or pressure readings that jump around.

Do a bench bypass test if you think there is an inside leak.

If you see or hear something strange, act fast. Quick checks and repairs keep your machines working and save you money.

You are important for keeping your hydraulic cylinder in good shape. Good training helps you use the equipment the right way. When you know how to use the controls and understand the limits, you make fewer mistakes. Training also teaches you to look for problems and use safety features. This means less wear, fewer accidents, and better energy use. If you and your team keep learning, your equipment will last longer and work better every day.

Sometimes, you can fix small problems on your own. Other times, you need expert guidance on maintenance to keep your equipment safe. Watch for these warning signs that tell you it is time to call a professional:

Hydraulic fluid leaks show up under your machine.

The cylinder moves slowly or acts in a strange way.

You hear odd noises or feel shaking when the cylinder works.

The system gets too hot or you notice sudden drops in pressure.

You see damage like pitted rods or rust on the cylinder.

If you notice any of these, do not wait. A trained technician can check for deeper issues and stop bigger problems before they start. Quick action can save you money and keep your team safe.

Tip: Trust your instincts. If something feels wrong, it is better to get help than risk a breakdown.

Picking the right company for cylinder repair makes a big difference. You want someone who knows what they are doing and cares about your equipment. Use this table to help you choose:

|

Criteria |

Description |

|---|---|

|

Product Quality |

Pick a provider with strong quality control and certifications like ISO 9001. |

|

Technical Expertise |

Make sure they can handle your special needs and offer custom solutions. |

|

Production Capacity |

Check if they can deliver on time and handle your order size. |

|

After-sales Service |

Look for good support, fast help, and advice after the repair is done. |

|

Reputation |

Read reviews and ask others about their experience with the company. |

Ask questions before you decide. Find out if the company offers clear answers and stands behind their work. A good provider will help you understand what went wrong and how to prevent it next time.

Note: The right service partner will keep your machines running longer and help you avoid future trouble.

You can make your reach cylinder last longer with easy steps. Look at your equipment often to check for problems. Check the seals, hoses, and fluid to see if they are good. Use good hydraulic fluids and keep your machine clean. Follow a schedule for maintenance and watch the system’s temperature. These habits help you find small problems before they get worse. This way, you can stop big repairs from happening. If you want to feel sure your machine is safe, make a maintenance plan or ask a professional to check it.