A lift cylinder uses hydraulic power to move heavy things up and down. You can see lift cylinders in many places like farms, building sites, and recycling plants. These cylinders help machines lift, push, or hold equipment. People use hydraulic lift systems in factories, big machines, and moving machines.

A lift cylinder helps move heavy things up or down. This tool is very strong and is used in many machines. It works by using hydraulic power to make things move. You can find it in machines that need to lift, push, or hold big items. The cylinder is shaped like a metal tube with a rod that slides in and out. When you use a hydraulic lift, it moves smoothly and with a lot of strength.

If you look at a telescopic hydraulic lift cylinder for dump truck and compare it to other actuators, you will see it can make much more force. Here is a table that shows how much force different actuators can make:

|

Actuator Type |

Force Output Capability |

|---|---|

|

Hydraulic Cylinders |

Extremely high forces because of high pressure (1800 to 5000 psi). Smaller cylinders can make big forces (like 15,000 lbf to 43,000 lbf). |

|

Electric Actuators |

Can make strong forces but need careful sizing. They may not reach very high forces unless made bigger. Force comes right away from the servo motor. |

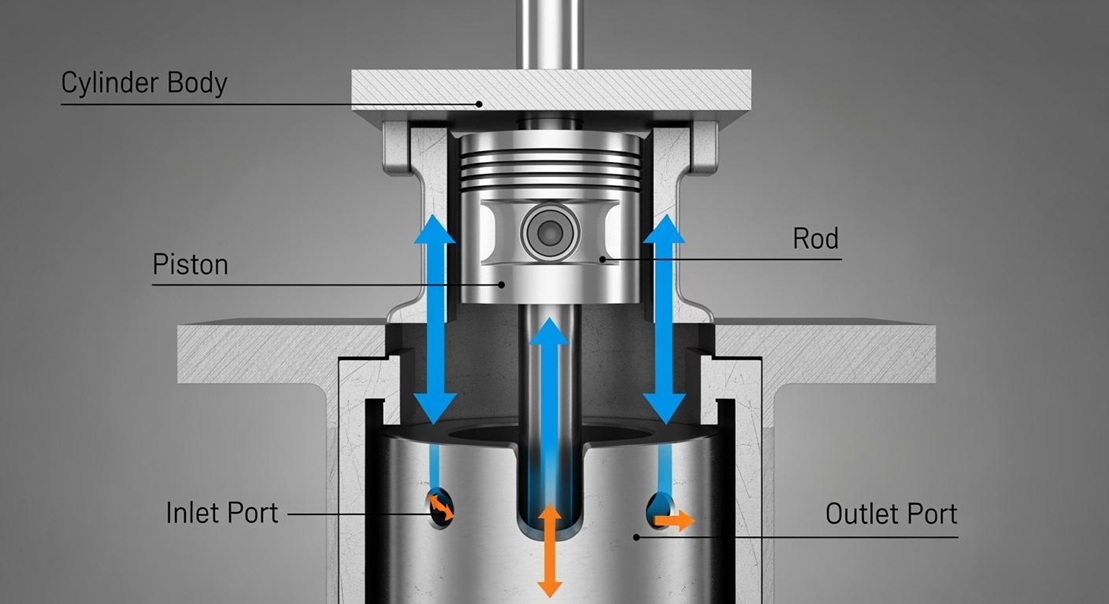

A hydraulic lift cylinder changes hydraulic energy into straight-line movement. You see this when a machine arm lifts something or a platform goes up. The cylinder uses pressurized fluid to push a piston inside the tube. This makes the rod move out or pull back in. You get strong and steady movement every time.

Here are the main jobs of a hydraulic lift cylinder:

It turns hydraulic energy into movement.

It makes straight force and motion.

It helps lift or move heavy things in many jobs.

You can count on a hydraulic lift to work smoothly and be very efficient. If you compare different lifting systems, you will see hydraulic lifts are best for heavy lifting and working all the time. Here is a table that compares hydraulic lifts and mechanical lifts:

|

Lift Type |

Efficiency Characteristics |

Performance Characteristics |

|---|---|---|

|

Hydraulic Lifts |

Very efficient for lifting heavy things and moving smoothly. |

Great for heavy lifting and working all the time. |

|

Mechanical Lifts |

Work well for lighter loads and careful tasks. |

Good for steady and exact movements. |

A hydraulic lift cylinder gives you the strength and dependability you need for hard work.

You might ask, "how does it work" when you see a lift cylinder. The answer is easy. A hydraulic lift cylinder uses pressurized oil to make straight movement. This movement lets you lift heavy things without much effort.

Here is how a hydraulic cylinder works step by step:

The hydraulic pump takes oil from a tank and pushes it into the cylinder barrel.

The oil goes into one side of the cylinder and pushes the piston.

The piston moves and pushes the piston rod out.

The piston rod moves what is attached, like a platform or machine arm.

When you want to lower the load, the oil goes back to the tank, and the piston returns to its first position.

Tip: The way the cylinder moves depends on how much oil and pressure you use. Valves help control where the oil goes, so you can lift or lower things smoothly.

You see hydraulic lift cylinders in many hydraulic lift systems. These systems use hydraulic actuators to move things up and down. The main job is to turn hydraulic pressure into useful work, like lifting or pushing. This is why you find hydraulic lift cylinders in machines that handle heavy loads.

Not all hydraulic lift cylinders work the same way. There are two main types: single-acting and double-acting. Each type moves and controls the lift in its own way.

|

Feature |

Single-Acting |

Double-Acting |

|---|---|---|

|

Fluid Ports |

Single port for oil entry |

Two ports for oil entry and exit |

|

Operation |

Unidirectional extension only |

Bi-directional extension and retraction |

|

Retraction Mechanism |

Relies on external forces (spring, gravity) |

Uses pressurized oil for both extension and retraction |

|

Complexity |

Simpler design, lower cost |

More complex design, higher cost |

|

Control |

Limited control over retraction speed |

Precise control over both extension and retraction |

Single acting telescopic cylinders have one port for oil. The oil pushes the piston out, and the rod extends. To bring the rod back, you need something else, like a spring or gravity. This type is simple and easy to use. You see it where you only need to lift or push in one direction.

Double-acting hydraulic lift cylinders have two ports. Oil can go on either side of the piston. This lets you extend and retract the rod with hydraulic power. You get more control over the movement. This type is good when you need to lift and lower with care.

Note: Double-acting cylinders are faster and stronger. They use less energy and give you better control. Single-acting cylinders cost less and are easier to take care of, but they only move in one direction.

Pick the right type for your job. If you need to lift and lower heavy things with control, a double-acting hydraulic lift cylinder is best. If you only need to lift or push one way, a single-acting cylinder works well.

Hydraulic systems use both types of hydraulic actuators. You see them in many machines, like construction equipment and factory lifts. Each type helps you move heavy things safely and easily.

You can think of the cylinder barrel as the main body of a hydraulic lift cylinder. It holds the pressure and keeps everything in place during operation. Most barrels use strong materials like steel or special alloys. These materials help the barrel handle high pressure and heavy loads. The inside of the barrel is very smooth. This smooth surface lets the piston move easily and keeps the hydraulic lift working well. Some barrels have coatings that stop rust and wear, so your hydraulic system lasts longer.

Tip: If you want your hydraulic lift to last for many years, check the barrel for damage and keep it clean.

The piston and rod work together to move things in a hydraulic lift. The piston sits inside the barrel and splits it into two parts. When hydraulic fluid enters, it pushes the piston, which makes the rod move out or in. The rod connects the hydraulic actuator to the machine part that needs to lift or push. If you use a larger rod, you get less force when pulling. A smaller rod gives you more force. The size of the rod and the length it moves (stroke length) can change how much weight your hydraulic lift can handle. You need to pick the right size for your application.

The piston takes the force from the hydraulic fluid.

The rod moves through the cylinder head and connects to the machine.

The stroke length and rod size affect how much you can lift.

Seals and ports keep your 40 ton telescopic hydraulic lift cylinder working without leaks. Seals stop oil from escaping and block dirt from getting inside. You find different types of seals in a hydraulic cylinder:

Piston seals keep oil from leaking between the piston and barrel.

Rod seals stop oil from leaking where the rod comes out.

Wiper seals clean the rod as it moves, keeping dirt out.

O-ring seals make tight seals between parts that do not move.

|

Seal Type |

Function |

Material Options |

|---|---|---|

|

Rod Seals |

Prevent leakage between rod and cylinder head |

Polyurethane, Rubber, PTFE |

|

Piston Seals |

Seal space between piston and cylinder bore |

Polyurethane, Rubber, PTFE |

|

Wiper Seals |

Scrape dirt from the piston rod |

Rubber, Polyurethane, Thermoplastic |

|

O-ring Seals |

Seal between parts that do not move |

Rubber, PTFE |

Ports are the openings where hydraulic fluid enters and leaves the cylinder. Good seals and ports help your hydraulic lift systems work smoothly and safely. If you keep these parts in good shape, your hydraulic actuators will last longer and handle heavy loads without trouble.

There are different hydraulic cylinder types for many machines. Each type is made for a certain job. Here are some common types you might find:

Welded cylinders are small and fit in tight spaces. They can handle high pressure without breaking.

Tie-rod cylinders are strong and support heavy loads. You often see them in big factory machines.

Telescopic cylinders are good for long strokes in small spaces. These work well in dump trucks and some lifts.

You should also know about single-acting and double-acting cylinders. Single-acting cylinders only move one way. They use gravity or springs to go back. You see these in jacks, lifting tools, and some car brakes. Double-acting cylinders move both ways. They give you more control and are used in machines that need careful movement, like molding machines.

Hydraulic lift cylinders are important in many machines. In aerial lifts, you see them in scissor lifts and boom lifts. Scissor lifts use a special system to lift people or tools up high. You find these lifts in factories and on building sites. Boom lifts use hydraulic cylinders to move the arm and platform. They help you reach hard places and keep the platform steady.

Hydraulic boom lifts move smoothly and are easy to control. You can use them for many jobs, like building or fixing things.

In building work, hydraulic cylinders help move heavy things. You see them in excavators, loaders, and bulldozers. They lift, tilt, and move buckets, blades, and arms. In car shops, hydraulic lift cylinders raise cars and trucks. This helps you work safely under the car. These cylinders also help dump trucks unload heavy stuff.

Hydraulic cylinders are used in many fields. You can trust hydraulic systems to lift, move, and control heavy machines every day.

You count on hydraulic lift cylinders to lift things easily.

They use pressurized fluid to move heavy stuff safely.

There are different types for each job, like aerial lifts or excavators.

New smart features help make machines safer and work better.

|

Main Part |

What It Does |

|---|---|

|

Pump |

Sends fluid to make lifting power |

|

Cylinder |

Pushes the piston and rod to lift things |

|

Reservoir |

Holds the hydraulic fluid |

|

Control Valve |

Guides fluid for smooth, careful movement |

Doing regular checks keeps your machines safe and ready to use.